Q367F Fixed Worm Gear Buried Welded Ball Valve product features:

1, The fire structure design:

According to API607 / BS6755 norms, the use of fire in the valve site, the secondary seal made of non-metallic materials in the ring decomposition or destruction under high temperature, then the primary metal seal can quickly close the ball Play a seal. Unique double-stage sealing seat structure design to ensure the reliability of the valve seat fire.

2, Anti-static design:

The use of spring and ball electrostatic leads to the device through the valve stem to form an electrostatic channel between the ball, so that the ball and the ring in the process of friction generated by static electricity lead to the earth through the valve body to prevent Electrostatic sparks may cause a fire or explosion hazard.

3, The sealed emergency ambulance and valve lubrication

Valve seat and stem seals appear damaged, there can be leakage through the injection valve sealing grease to achieve the role of instantaneous seal. The valve under normal working conditions, you can inject grease through the grease injection valve stem and spherical lubrication, the valve opening and closing more flexible and lightweight.

4, Seat structure design:

A. Both the upstream and downstream single piston seat:

with double blocking / double discharge function, can simultaneously cut off from the upstream and downstream media; with automatic pressure relief function: valve cavity retention media due to temperature Of the increase in the case of abnormal pressure booster, the valve seat can automatically pressure relief (discharge to the low pressure end).

B. Double piston seats are used both upstream and downstream:

With double blocking function, it can cut off the medium from the upstream and downstream simultaneously. The medium in the valve cavity of the valve can not be automatically discharged, and a relief valve needs to be set on the valve body to set the pressure Relieve abnormal pressure rise in the valve chamber.

C. Upstream with single-piston valve seat, downstream with dual-piston valve seat:

With double blocking function, which can cut off the medium from the upstream and downstream simultaneously; with automatic directional pressure relief function: valve medium stagnant medium due to temperature rise, In the event of an abnormal pressure boost, the valve seat can automatically relieve pressure (to the upstream side)

5, Installation of drive installation platform

ISO5211 valve flange design, through the use of brackets and coupling sleeve, easy to install any type of drive.

6, lengthened stem:

For the installation of the valve buried, according to the needs of installation and operation of the valve stem can be lengthened, lengthen the stem size according to customer requirements. All sewage pipes, exhaust pipes and emergency grease devices are lengthened accordingly, other related pipeline close to the extended parts of the valve, the valve drain valve, vent valve and grease valve connected to the ground installation in order to carry out regular maintenance of the main valve, Valve surface covered with normative corrosion-resistant asphalt, polyurethane or epoxy coating, in order to adapt to the installation and use of buried conditions.

7, Lengthen the valve cover:

For the valve which requires to work at low temperature, it increases the distance between the valve body and the sealing area of the valve stem by lengthening the valve cover to avoid the influence of temperature on the seal. The lengthened height can also be determined according to the standard rules According to the customer's request.

8, The valve structure:

Valves with three body side forging welding structure, eliminating the import pressure to promote the ball seal seat formed a huge sealing load caused by excessive torque. The spherical surface finish of the sphere and the use of inserts with good self-lubricating inserts allow for smaller opening and closing torques even at the highest operating pressures.

9, The structural characteristics of welding: the

Body around the body with a typical narrow gap submerged arc welding using a special flux used in welding with the required current-carrying and slag removal effect, the welding particle size smaller, High toughness to meet the welding performance of the metal. Welding 100% ultrasonic testing and hardness testing to ensure the welding quality of the weld.

10, Finite element analysis:

The valve housing and the inner parts are carefully designed to ensure reliable operation under various operating conditions. The strength of the valve housing, the inner force of the inner part and the operating torque of the valve stem are measured by finite element analysis Simulation analysis of conditions, for easy problems and weaknesses to optimize, to ensure superior valve performance.

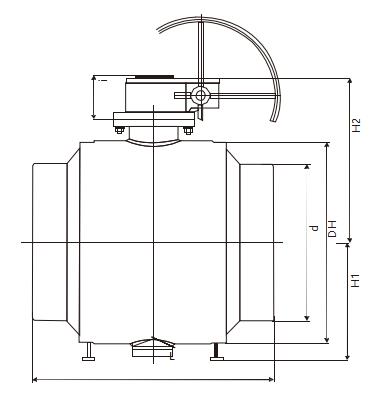

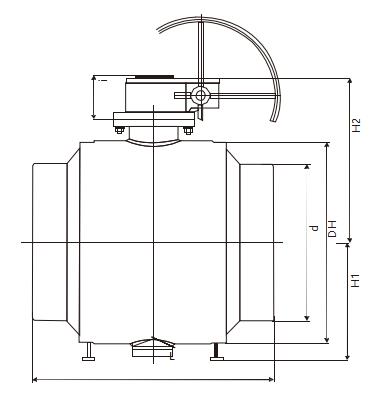

Q367F Fixed Worm Gear Buried Welded Ball Valve product size: PN16/PN20/CLASS150

|

DN

|

NPS

|

L

|

H1

|

H2

|

W

|

Weight(kg)

|

Torque(N.M)

|

|

RF

|

WE

|

RJ

|

WE

|

RF/RJ

|

|

50

|

2

|

178

|

216

|

191

|

99

|

210

|

300

|

22

|

25

|

42

|

|

65

|

2 1/2

|

191

|

241

|

203

|

110

|

215

|

350

|

30

|

35

|

68

|

|

80

|

3

|

203

|

283

|

216

|

120

|

225

|

400

|

35

|

40

|

92

|

|

100

|

4

|

229

|

305

|

241

|

148

|

255

|

650

|

48

|

95

|

145

|

|

150

|

6

|

394

|

457

|

406

|

218

|

237

|

460

|

190

|

230

|

210

|

|

200

|

8

|

457

|

521

|

470

|

260

|

290

|

600

|

250

|

295

|

625

|

|

250

|

10

|

533

|

559

|

546

|

292.5

|

323.5

|

600

|

400

|

430

|

835

|

|

300

|

12

|

610

|

635

|

622

|

327.5

|

359.5

|

750

|

550

|

620

|

1150

|

|

350

|

14

|

686

|

762

|

699

|

365

|

395

|

750

|

820

|

900

|

1560

|

|

400

|

16

|

762

|

838

|

775

|

437.5

|

436.5

|

750

|

1100

|

1220

|

2375

|

|

450

|

18

|

864

|

914

|

876

|

485

|

487.5

|

750

|

1400

|

1550

|

2850

|

|

500

|

20

|

914

|

991

|

927

|

522.5

|

525

|

750

|

1750

|

1950

|

3580

|

|

550

|

22

|

991

|

1092

|

1004

|

575.5

|

560

|

750

|

2200

|

2350

|

4275

|

|

600

|

24

|

1067

|

1143

|

1080

|

607.5

|

617.5

|

750

|

2800

|

3050

|

5650

|

|

650

|

26

|

1143

|

1245

|

1156

|

640

|

632.5

|

750

|

2900

|

3250

|

6520

|

|

700

|

28

|

1245

|

1346

|

1286

|

670

|

682.5

|

750

|

3400

|

3700

|

7380

|

|

750

|

30

|

1295

|

1397

|

1308

|

710

|

760

|

750

|

4800

|

5300

|

8380

|

|

800

|

32

|

1372

|

1524

|

1385

|

730

|

780

|

750

|

5500

|

6000

|

9370

|

|

850

|

34

|

1473

|

1626

|

1486

|

780

|

830

|

750

|

7650

|

8550

|

12065

|

|

900

|

36

|

1524

|

1727

|

1537

|

830

|

880

|

750

|

8865

|

9845

|

14760

|

|

1000

|

40

|

1753

|

1956

|

1985

|

875

|

920

|

750

|

12350

|

13560

|

18465

|

|

1050

|

42

|

1829

|

2083

|

2155

|

910

|

945

|

750

|

13250

|

14280

|

29210

|

|

1200

|

48

|

2032

|

2388

|

2418

|

1070

|

1085

|

750

|

20500

|

21800

|

44500

|